Rockwool Production Line Manufacture Electrical Roofing Rockwool Pu

Sandwich Panel Machine

EPS/rock wool sandwich panel production line consists of single

level roll forming machine,composite equipment and cutting

equipment,it integrates the technology of cold roll and

compositing,this product line can make composted corrugated roof

sandwich panel at a time.It also can make wall sandwich panel. the

core material can be chosen Polystyrene(EPS)and rock wool. The roll

forming machine and composite equipment can separately produce.

EPS/rock wool sandwich panel production line consists of uncoiling

system,film covering and shearing system,roll forming

system,compositing system,heating system,glue scratching

system,shearing system,conveying rollers,electric controlling

system,pneumatic system and so on.We can design different kinds of

profile and fittings for machine,as per customers’ requirements.

Working Flow

Uncoiling-Roll Forming-Pre-cutting(if needed)-Heating-Glue

Scratching-EPS Feediong-Compositing-Measuring

Length&Shearing-Sheet to support table

Technique parameters of the processing line

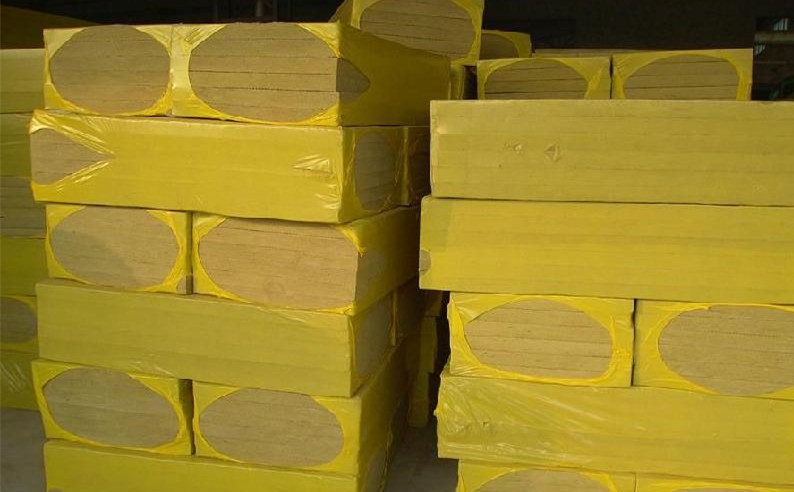

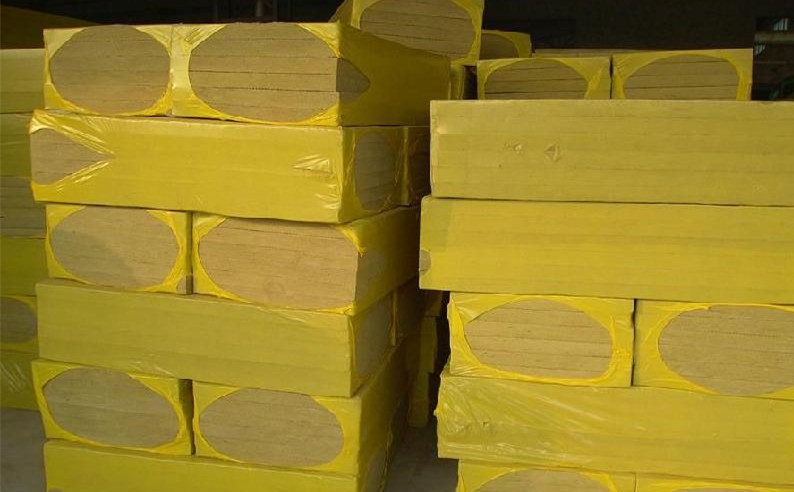

(1) Coil material: EPS, rock wool, glass silk floss and so on

(2) Thickness of the plate: 0.3-0.8mm

(3) Core thickness: 20-300mm

(4) Production capacity (according to your glue):

4-4.5m/min (the fastest), 2-2.5m/min(the slowest)

(5) Total power: about 30KW

(6) Weight: 25ton

(7) PLC control systerm, easy to operate, high precision and work

stably.

(8) Dimensions of whole production line:

About Length45000mm × Width3600mm × Height3300mm

| 1 | Raw material system | 1)Feeding system

2) Automatic proportioning machine

3)Control cabinet (PLC is adopted)

4)Feeding machine |

| 2 | Melting system | 1) Furnace platform

2)Cupola furnace

3) Material level control system

4)Dust catcher

5)Waste gas burning furnace

6)Waste gas intake pipe

7)Waste gas intake fan

8)Heat ex-changer

9)Control cabinet

10) Melting furnace cooling system

11)Wind supply fan for the melting furnace

12)Wind supply pipeline for melting furnace |

| 3 | Fiber-forming system | 1) High speed centrifuge

2)Fan

3)Fiber blowing bellows

4)Lubricating system of centrifuge

5)Water pump and water cooling system

6)Electrical control cabinet(PLC)

7) Residue-remover |

| 4 | Wool collecting and allocation system &

Board making system | 1)Wool collector and Pendulum wool allocation machine

2) Control cabinet

3) Air-intake fan for wool collecting

4)Dust filtering system of wool collecting part

5) Wool allocation conveyor

6)Compressing pleating machine

7) Curing oven

8)Main power assembly

9) Control cabinet |

| 5 | Curing oven explosion-proof system | 1) Natural gas inspect system

2)Explosion-proof fan

3)Explosion-proof pipes

4)Control cabinet |

| 6 | Cutting system | 1)Cooling conveyor2) Cooling fan

3) Thickness saw

4)Cooling cutter

5)Metering device of cutting

6)Control cabinet

7)Cutting machine driving system |

| 7 | Dust-removing system of cutting part | 1)Bag-type dust filter

2)Dust-removing pipes

3)Dust-removing fan |

| 8 | Scrap recycling machine | 1)Crusher

2)Scrap-recycling fan

3) Scrap-recycling pipeline |